Page 18 - A-PLAS2024 E-Directory

P. 18

MOTAN (THAILAND) CO., LTD.

our expert know-how we go beyond the limits of

traditional materials handling and take it to the next level.

In practice this means identifying the material

management of a production chain, designing it according

to customer requirements and then optimizing it. We

focus on our core areas of drying, dosing & mixing,

conveying, controls and storage, because this is what we

specialize in.

This interdisciplinary approach enables us to offer our customers high quality

products and equipment in more than one market segment. Our modular and

networked products address the needs of our customers, while at the same time

meeting the latest industry standards in terms of digitalization, Industry 4.0 and

circular economy.

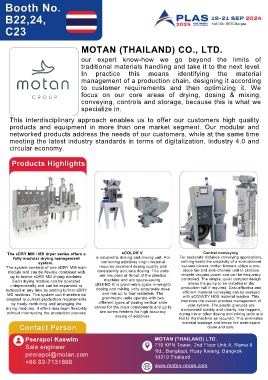

The sDRY MM / MD dryer series offers a sCOLOR V Central conveying

fully modular drying management is volumetric dosing and mixing unit. For For moderate distance conveying applications,

system. combining additives virgin material nothing beats the simplicity of a side-channel

The system consists of one sDRY MM main requires excellent mixing quality and vacuum blower. motan blowers utilize a one-

module and can be flexibly combined with consistently accurate dosing. The units piece fan and side-channel unit to produce

up to twelve sDRY MD drying modules. are mounted at throat of the plastics reliable vacuum power and can be frequency

Each drying module can be operated machine and are space-saving. controlled. The simple, quiet compact design

allows the pump to be installed in the

independently and can be expanded or sBLEND G is gravimetric (gain-in-weight) production hall if required. Cost-effective and

reduced at any time by adding further sDRY dosing and mixing units accurately dose efficient material conveying can be realized

MD modules. The system can therefore be and mix up to four materials. The with sCONVEY HOS material loaders. This

adapted to current production requirements gravimetric units operate with two improves the overall process management of

by freely combining and arranging the different types of dosing vertical slide your system. The plastic granules are

drying modules. It offers maximum flexibility valves for the main components and up to transported quickly and cleanly into hoppers,

without interrupting the production process two screw feeders for high accuracy drying bin or other dosing and mixing units and

dosing of additives.

fed to the machine as required. This eliminates

material wastage and keeps the work-space

clean and safe.

Peerapol Kaewim MOTAN (THAILAND) LTD.

Sale engineer 719 KPN Tower, 2nd Floor Unit A, Rama 9

Rd., Bangkapi, Huay Kwang, Bangkok

peerapol@motan.com

10310 Thailand

+66 82-7131868

www.motan-group.com